This

Cylinder boasts outstanding performance tailored to industrial application needs, with core advantages that balance reliability and usability. First, it complies with the ISO15552 standard, ensuring compatibility with global industrial mounting and connection specifications, making it easy to integrate into existing automated systems. Second, the piston seal uses two Y-type one-way sealing rings; these rings have a compensation function, which extends the cylinder’s service life and lowers its minimum starting pressure—this allows smooth operation even in low-pressure working environments.

Additionally, the Cylinder’s buffer adjustment works smoothly and offers a long buffer distance. This design effectively reduces impact force when the piston reaches the end of its stroke, protecting both the cylinder body and connected equipment from damage. Moreover, its cylinder bearings and wear-resistant rings feature an extended spacing, which enhances lateral load performance. This means the cylinder can maintain stable operation even when bearing side forces, adapting to complex installation scenarios where lateral pressure may occur.

Finally, the cylinder’s front cover, rear cover, and piston all use high-pressure casting technology. This process not only gives the cylinder a neat, attractive appearance but also significantly improves its structural strength, making it more resistant to external impacts and wear during long-term use. Overall, this cylinder combines standard compliance, durability, and stability, ideal for pneumatic automation equipment in machinery, electronics, and packaging industries.

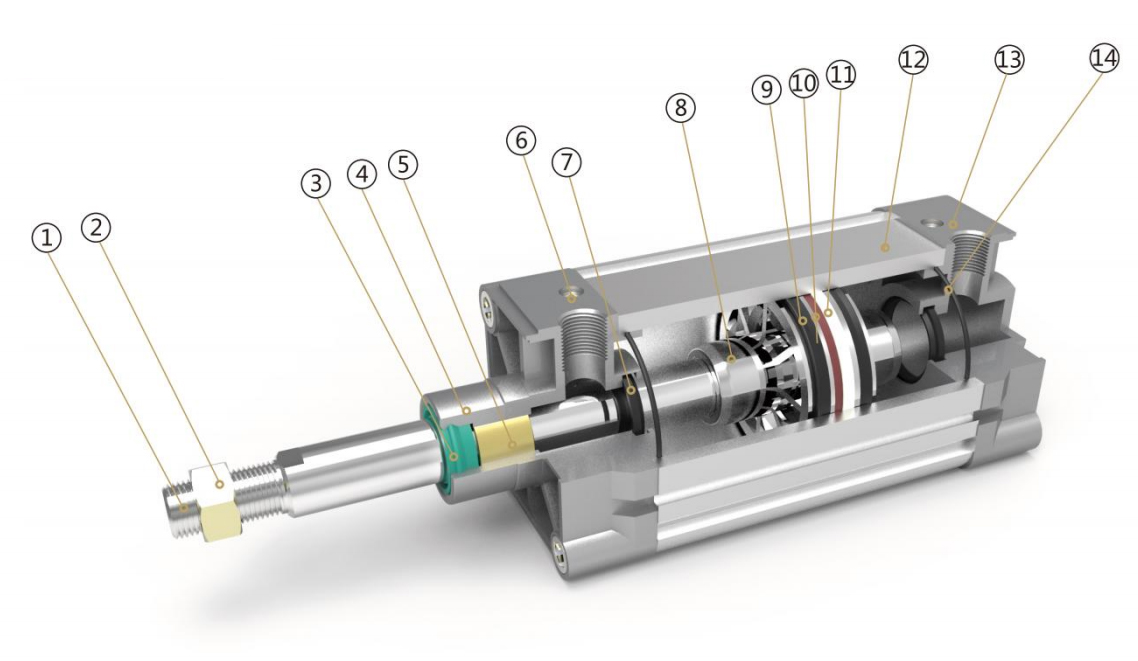

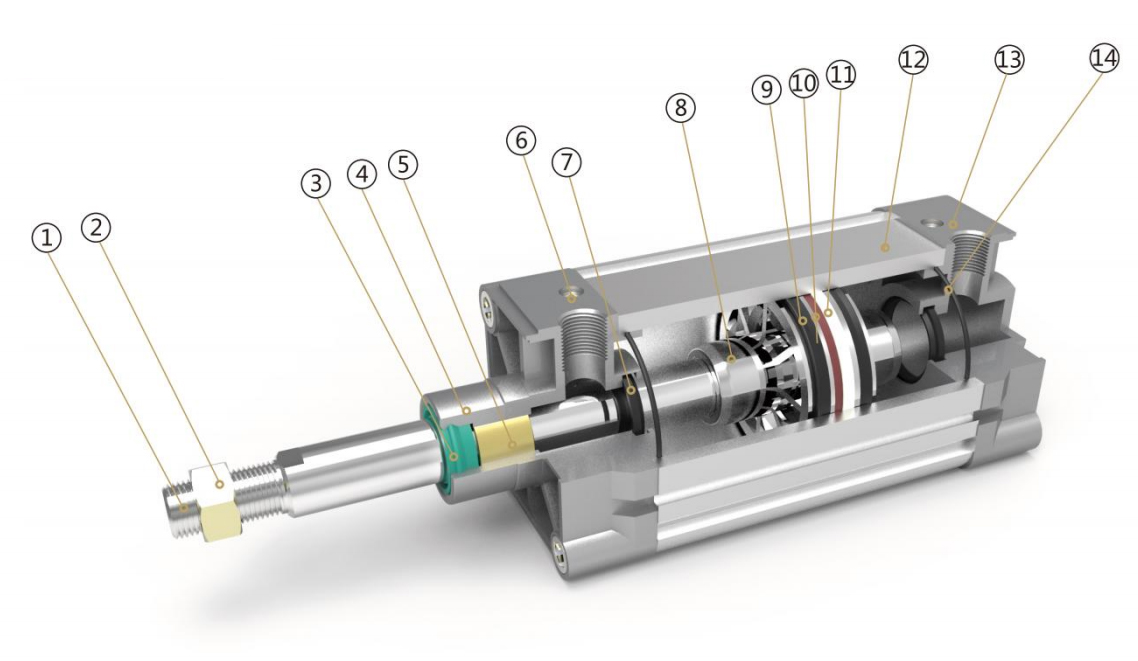

Internal Structure

Parts

| Number |

Name |

Number |

Name |

| 1 |

Piston rod |

8 |

Piston |

| 2 |

Hexagon nut |

9 |

Y ring |

| 3 |

Shaft seal |

10 |

Magnet |

| 4 |

Front cover |

11 |

Anti-friction ring |

| 5 |

Copper tube |

12 |

Barrel |

| 6 |

Cushion adjust screw |

13 |

Back cover |

| 7 |

Cushion seal |

14 |

O ring |

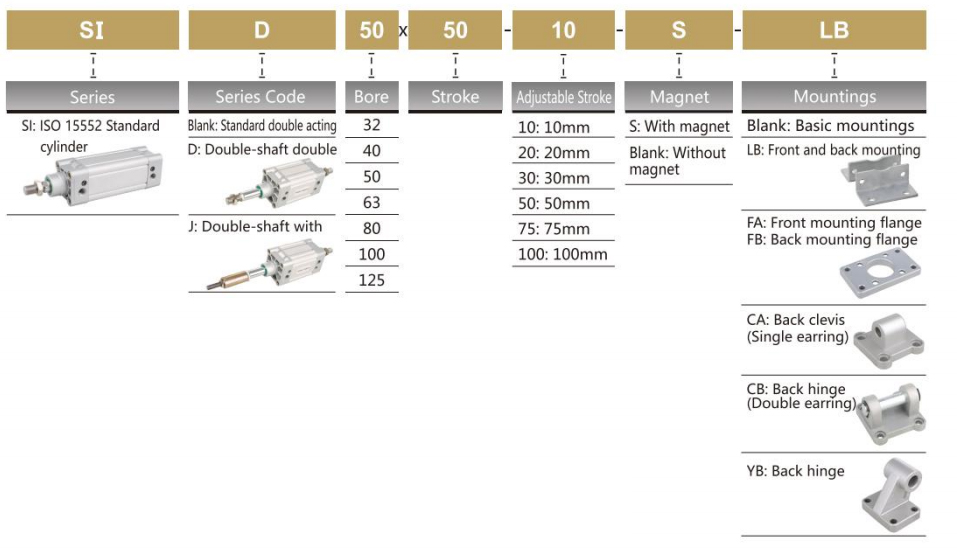

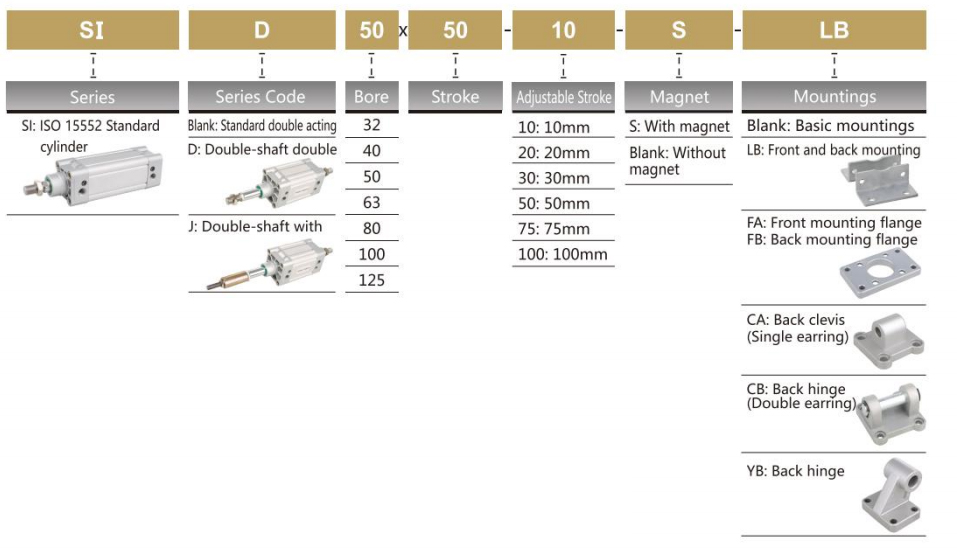

Ordering Code

*Sensor model JEL-30, please refer to P173 for the specific ordering code.

Specification

| Bore (mm) |

32 |

40 |

50 |

63 |

80 |

100 |

125 |

| Operation |

Double Acting |

| Working Medium |

Air |

| Mountings |

Basic FA FB CA CB LB YB |

| Operating Pressure Range |

1~9.0 Kgf/cm² |

| Proof Pressure |

13.5 Kgf/cm² |

| Operating Temperature Range |

-20~80℃ |

| Operating Speed Range |

50~800mm/s |

| Cushion |

Adjustable Cushion |

| Adjustable Cushion Stroke |

20mm |

26mm |

| Port Size |

G1/8″ |

G1/4″ |

G3/8″ |

G1/2” |

Stroke

| Bore |

Standard Stroke |

Max.Stroke |

Allowable Stroke |

| 32 |

25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 |

1000 |

2000 |

| 40 |

25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 |

1200 |

2000 |

| 50 |

25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 |

1200 |

2000 |

| 63 |

25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 |

1500 |

2000 |

| 80 |

25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 |

1500 |

2000 |

| 100 |

25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 |

1500 |

2000 |

| 125 |

25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 |

1500 |

2000 |

Cylinder